|

|

| Menu location |

|---|

| Gear → Involute Gear |

| Workbenches |

| FCGear |

| Default shortcut |

| None |

| Introduced in version |

| v0.16 |

| See also |

| FCGear CycloideGear |

Descripción

Debido a la favorable relación de engrane y su fabricación relativamente sencilla, el dentado de espiral es la forma de diente más común en la construcción de máquinas. Las ruedas dentadas se encuentran allí donde se desea transferir movimiento y fuerza de una pieza a otra. Se pueden encontrar, por ejemplo, en máquinas, coches, relojes o electrodomésticos. A menudo, el movimiento se transmite directamente de una rueda dentada a otra, pero a veces también a través de una cadena. Además, se puede cambiar el sentido de giro. También es posible cambiar un movimiento radial a uno lineal mediante un cremallera involuta.

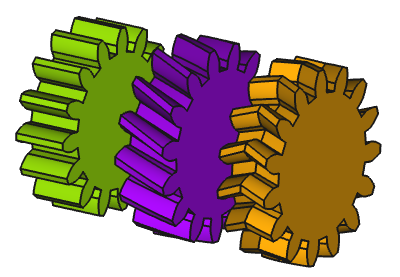

De izquierda a derecha: engranaje recto, engranaje helicoidal, engranaje helicoidal doble

Uso

- Cambie a

entorno de trabajo FCGear.

- Hay varias formas de invocar el comando:

- Presione el botón

engranaje evolvente en la barra de herramientas.

- Seleccione la opción Gear →

Engranaje evolvente del menú.

- Presione el botón

- Cambie el parámetro de engranaje a las condiciones requeridas (ver Propiedades).

Propiedades

Un objeto FCGear InvoluteGear se deriva de un objeto Part Feature y hereda todas sus propiedades. También tiene las siguientes propiedades adicionales:

Datos

accuracy

- Datosnumpoints (

Integer): Default is20. Change of the involute profile. Changing the value can lead to unexpected results. - Datossimple (

Bool): Default isfalse,truegenerates a simplified display (without teeth and only a cylinder in pitch diameter).

base

- Datosheight (

Length): Default is5 mm. Value of the gear width. - Datosmodule (

Length): Default is1 mm. Module is the ratio of the reference diameter of the gear divided by the number of teeth (see Notes). - Datosnum_teeth (

Integer): Default is15. Number of teeth (see Notes).

computed

- Datosaddendum_diameter (

Length): Default is17 mm. Outside diameter, measured at the addendum (the tip of the teeth). - Datosangular_backlash (

Angle): (read-only) The angle by which this gear can turn without moving the mating gear. - Datospitch_diameter (

Length): Default is15 mm. The pitch diameter. - Datosroot_diameter (

Length): (read-only) The root diameter, measured at the foot of the teeth. - Datostransverse_pitch (

Length): Default is3.14 mm. The transverse pitch. - Datostraverse_module (

Length): Default is1 mm. The traverse module of the generated gear.

fillets

- Datoshead_fillet (

Float): Default is0 mm. A fillet for the tooth-head. - Datosroot_fillet (

Float): Default is0 mm. A fillet for the tooth-root. - Datosundercut (

Bool): Default isfalse,truechanges the profile of the tooth root (see Notes).

helical

- Datosdouble_helix (

Bool): Default isfalse,truecreates a double helix gear (see Notes). - Datoshelix_angle (

Angle): Default is0 °. With the helix angle β a helical gear is created – positive value → rotation direction right, negative value → rotation direction left (see Notes). - Datosproperties_from_tool (

Bool): Default isfalse. Iftrueand Datoshelix_angle is not zero, gear parameters are recomputed internally for the rotated gear.

hole

- DatosAxle_hole (

Bool): Default isfalse.trueenables a central hole for an axle. - DatosAxle_holesize (

Length): Default is10 mm. Diameter of the hole for an axle. - Datosoffset_hole (

Bool): Default isfalse,trueenables an offset hole. - Datosoffset_holeoffset (

Length): Default is10 mm. The offset of the offset hole. - Datosoffset_holesize (

Length): Default is10 mm. The diameter of the offset hole.

involute

- Datospressure_angle (

Angle): Default is20 °(see Notes). - Datosshift (

Float): Default is0. Generates a positive and negative profile shift (see Notes).

tolerance

- Datosbacklash (

Length): Default is0. Backlash, also called lash or play, is the distance between the teeth at a gear pair. - Datosclearance (

Float): Default is0.25(see Notes). - Datoshead (

Float): Default is0. This value is used to change the tooth height. - Datosreversed_backlash (

Bool):truebacklash decrease orfalse(default) backlash increase see Notes).

version

- Datosversion (

String):

Notas

- beta: When beta is changed, pitch diameter also changes. The following formula illustrates how the parameters interact: d = m * Z / cos beta (Z = number of teeth, d = pitch diameter, m = module). This means for the spur gear: cos beta = 0 and for the helical gear: cos beta > 0. However, a helix angle of less than 10° has hardly any advantages over straight teeth.

- clearance: At a gear pair, clearance is the distance between the tooth tip of the first gear and the tooth root of the second gear.

- double_gear: To use the double helical gearing the helix angle β (beta) for the helical gearing must first be entered.

- module: Using ISO (International Organization for Standardization) guidelines, Module size is designated as the unit representing gear tooth-sizes. Module (m): m = 1 (p = 3.1416), m = 2 (p = 6.2832), m = 4 (p = 12.566). If you multiply Module by Pi, you can obtain Pitch (p). Pitch is the distance between corresponding points on adjacent teeth.

- shift: Profile shift is not merely used to prevent undercut. It can be used to adjust center distance between two gears. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner.

- teeth: If the number of teeth is changed, the pitch diameter also changes (dw).

- undercut: Undercut is used when the number of teeth of a gear is too small. Otherwise the mating gear will cut into the tooth root. The undercut not only weakens the tooth with a wasp-like waist, but also removes some of the useful involute adjacent to the base circle.

- pressure_angle: 20° is a standard value here. The pressure angle is defined as the angle between the line-of-action (common tangent to the base circles) and a perpendicular to the line-of-centers. Thus, for standard gears, 14.5° pressure angle gears have base circles much nearer to the roots of teeth than 20° gears. It is for this reason that 14.5° gears encounter greater undercutting problems than 20° gears. Important. the pressure angle changes with a profile shift. Only change the parameter, if sufficient knowledge of the gear geometry is available.

- reversed_backlash: If there are several gears, pay attention to which gear the parameter is set for.

Limitaciones

A 2D tooth profile, obtained by setting the Datosheight to zero, cannot be used with features requiring a 2D shape. For example PartDesign Pad and PartDesign AdditiveHelix features do not accept such a profile as base. For technical details, please refer to the related issue on GitHub.

Fórmulas útiles

Standard Spur Gears

Aquí "standard" se refiere a aquellos engranajes rectos sin coeficiente de cambio de perfil ().

| Symbol | Term | Formula | FCGear Parameter |

|---|---|---|---|

| Module | - | ||

| Number of Teeth | - | ||

| Pressure Angle | Typically, | ||

| Reference Diameter or Pitch Diameter | |||

| Addendum Coefficient | Typically, | ||

| Dedendum Coefficient | Typically, | ||

| Addendum | - | ||

| Dedendum | - | ||

| Tooth Height or Tooth Depth | Typically, |

- | |

| Profile Shift Coefficient | For standard gears, |

| Symbol | Term | Formula |

|---|---|---|

| Tip Diameter | Typically, | |

| Root Diameter | Typically, |

| Symbol | Term | Formula |

|---|---|---|

| Tip Diameter | Typically, | |

| Root Diameter | Typically, |

| Symbol | Term | Formula |

|---|---|---|

| Center Distance | ||

| Tip and Root Clearance | |

- Helical and double helical gearing

- pitch diameter (dw) = module * teeth : cos beta

- axle base = (pitch diameter (dw) 1 + pitch diameter (dw) 2) : 2

- addendum diameter = pitch diameter (dw) + 2 * module

- module = pitch diameter (dw) * cos beta : teeth

Programación

Utilice el poder de Python para automatizar el modelado de sus engranajes:

import FreeCAD as App

import freecad.gears.commands

gear = freecad.gears.commands.CreateInvoluteGear.create()

gear.teeth = 20

gear.beta = 20

gear.height = 10

gear.double_helix = True

App.ActiveDocument.recompute()

Gui.SendMsgToActiveView("ViewFit")

Esta página ha sido recuperada de https://wiki.freecad.org/FCGear_InvoluteGear