|

|

| Menu location |

|---|

| Gear → Involute Rack |

| Workbenches |

| FCGear |

| Default shortcut |

| None |

| Introduced in version |

| v0.16 |

| See also |

| FCGear InvoluteGear |

Description

Gear racks are used to convert a rotary motion into a linear motion or vice versa. The following examples show the different applications:

- A rack with gear on at a retaining weir.

- Various rack systems of rack-and-pinion railways.

- Rack and pinion steering in a vehicle.

- Rack and pinion winch as mechanical hoist (e.g. car jack).

- Pneumatic rack and pinion drives used to control valves in pipeline transport.

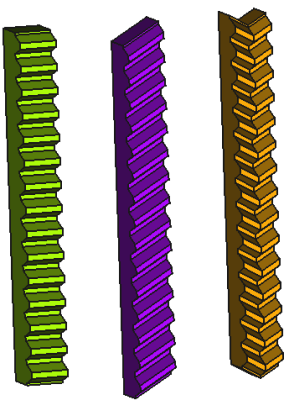

From left to right: Spur gearing, helical gearing, double helical gearing

Usage

- Switch to the

FCGear Workbench.

- There are several ways to invoke the command:

- Press the

Involute Rack button in the toolbar.

- Select the Gear →

Involute Rack option from the menu.

- Press the

- Change the gear parameter to the required conditions (see Properties).

Properties

An FCGear InvoluteRack object is derived from a Part Feature object and inherits all its properties. It also has the following additional properties:

Data

base

- Dataadd_endings (

Bool): Iftrue(default), then the total length of the rack is teeth * pitch. Iffalse, then the rack starts with a tooth-flank. - Dataheight (

Length): Default is5 mm. Value of the gear width. - Datamodule (

Length): Default is1 mm. Module is the ratio of the reference diameter of the gear divided by the number of teeth (see Notes). - Datateeth (

Integer): Default is15. Number of teeth. - Datathickness (

Length): Default is5. Height from the tooth root to the lower side of the rod.

computed

- Datatransverse_pitch (

Length): (read-only) Pitch in the transverse plane (see Notes).

fillets

- Datahead_fillet (

Float): Default is0 mm. - Dataroot_fillet (

Float): Default is0 mm.

helical

- Databeta (

Angle): Default is0 °. With the helix angle β a helical gear is created – positive value → rotation direction right, negative value → rotation direction left. - Datadouble_helix (

Bool): Default isfalse,truecreates a double helix gear (see Notes). - Dataproperties_from_tool (

Bool): Default isfalse. Iftrueand Databeta is not zero, gear parameters are recomputed internally for the rotated gear.

involute

- Datapressure_angle (

Angle): Default is20 °(see Notes).

precision

- Datasimplified (

Bool): Default isfalse,truegenerates a simplified display (without teeth).

tolerance

- Dataclearance (

Float): Default is0.25(see Notes). - Datahead (

Float): Default is0. This value is used to change the tooth height.

version

- Dataversion (

String):

Notes

- transverse_pitch: The value is the result of multiplication of module * pi. This means for the standard involute rack of FCGear: 15 (teeth) * 3.14 (transverse_pitch) is 47.12 mm. See also module further below.

- clearance: At a gear pair, clearance is the distance between the tooth tip of the first gear and the tooth root of the second gear.

- double_helix: To use the double helical gearing the helix angle β (beta) for the helical gearing must first be entered.

- module: Using ISO (International Organization for Standardization) guidelines, Module size is designated as the unit representing gear tooth-sizes. Module (m): m = 1 (p = 3.1416), m = 2 (p = 6.2832), m = 4 (p = 12.566). If you multiply Module by Pi, you can obtain Pitch (p). Pitch is the distance between corresponding points on adjacent teeth. The result of the multiplication is displayed in transverse_pitch

- pressure_parameter: Only change the parameter, if sufficient knowledge of the gear geometry is available.

Useful formulas

See FCGear InvoluteGear.

Scripting

Use the power of python to automate your gear modeling:

import FreeCAD as App

import freecad.gears.commands

gear = freecad.gears.commands.CreateInvoluteRack.create()

gear.teeth = 20

gear.beta = 20

gear.height = 10

gear.double_helix = True

App.ActiveDocument.recompute()

Gui.SendMsgToActiveView("ViewFit")

This page is retrieved from https://wiki.freecad.org/FCGear_InvoluteRack